Individual or Turnkey

Home > Services > Independent Services > Construction Management

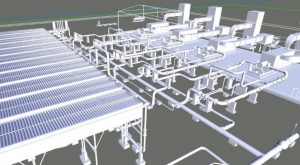

Construction Management

With a rare depth of in-field experience, EnSiteUSA can confidently manage project construction on behalf of our clients at the highest levels of efficiency and excellence.

This expertise extends nationwide. On your project, you’ll have highly qualified professionals with a comprehensive knowledge of industry codes, regulations and best practices for QA/QC. Our people understand pipeline and facility construction inside and out, beginning to end.

Credentials

Our construction management and inspection personnel conform to client-specific DOT Operator Qualification (OQ) requirements through OSHA, Veriforce, NCCER, MEA and other accredited OQ programs. EnSiteUSA complies with all DOT PHMSA drug and alcohol testing requirements and is a member of ISNetworld, which allows owners/operators to evaluate information pertaining to our company such as OQ and safety requirements.

Construction Management Capabilities:

- Project Controls (cost, schedule, and document control)

- Construction Planning

- Scheduling

- Contract Administration and Closeout

- Management of Change

- Cost Forecasting

- Participation in Bid Solicitation, Evaluation and Award Negotiation Support

- Certification and Commissioning

- Department of Transportation (DOT) Document Management

- Supply Chain Management

- Materials Management